Repairability, Modular Design, and Replacement Parts

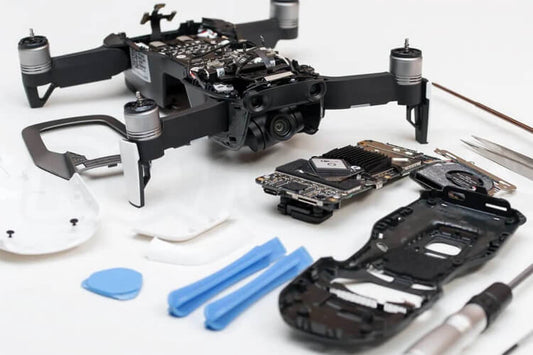

The DJI FPV drone is not only DJI’s first step into the FPV (First-Person View) market but also one of its most repair-friendly drones to date. A recent DJI FPV teardown video reveals a modular internal design that makes common repairs and part replacements far easier compared to older DJI models.

At first glance, the DJI FPV looks like a highly complex piece of engineering. However, once opened, the layout becomes surprisingly logical—highlighting DJI’s effort to make this drone more serviceable and customizable for users who want to keep flying without frequent professional repairs.

Replacement Parts Availability

DJI has already made some essential FPV replacement parts available on its official store, including:

-

Landing gear – $19

-

Gimbal and camera – $129

-

Arm braces – $19

While the current list is limited, it’s likely that DJI will expand its catalog. In addition, the third-party market for FPV drone parts is expected to grow, giving pilots even more options for customization and affordable repairs.

Easy-to-Disassemble: Screws, Not Glue

One of the most impressive aspects of the teardown is DJI’s assembly method. The entire DJI FPV drone is held together with screws, not glue. This means components can be removed and replaced without destructive prying. The only adhesive-like material found inside is the thermal pad used for cooling.

For deeper internal repairs, some soldering is required, but DJI has thoughtfully designed larger solder pads compared to its older drones. This makes component-level repairs far more approachable, even for beginners with a basic soldering kit.

Modular and Separated Components

The DJI FPV modular design makes repairs faster and more cost-effective:

-

GPS, flight controller, and ESC are placed on separate boards rather than being integrated into one unit.

-

The ESC board (a component prone to wear over time) is positioned at the rear with easy access, requiring just a few screws and desoldering to replace—an estimated 30-minute repair.

-

Motors, arms, and antennas are mounted with screws and plug-in connectors, allowing quick swaps after a crash.

This separation of parts means users don’t need to replace the entire motherboard for a single failure, significantly lowering repair costs.

Replaceable Gimbal and Camera

The gimbal camera is one of the most crash-prone parts of any FPV drone, and DJI anticipated this. Replacing the gimbal is straightforward:

-

Remove the canopy with a few screws.

-

Unscrew the bracket securing the gimbal cables.

-

Remove the gimbal assembly.

The process is fast and beginner-friendly, ensuring downtime is minimal. DJI also reinforced the drone with a metal protective plate that shields both the battery and internal boards, which doubles as a cooling system for the flight controller.

Final Thoughts

The DJI FPV teardown proves that DJI designed this drone with repairability and modularity in mind. By avoiding glue, separating key components, and providing spare parts, DJI has made its FPV drone one of the most serviceable products in its lineup.

For drone enthusiasts, hobbyists, and FPV racers, this means fewer costly professional repairs, easier DIY fixes, and more freedom to customize. As the aftermarket grows, the DJI FPV could become not just a flying machine but a fully customizable platform for drone pilots worldwide.